BATH, Maine — Danny Nadeau remembers well the day he was hired as an electrician at Bath Iron Works. He was fresh out of trade school in northern Maine.

“There wasn’t much work at the time up in northern Maine,” he said. “It was during a recession.”

Nadeau said he called the shipyard daily, and sometimes twice a day, for about three months “until they got sick of hearing from me.” When he arrived for his interview, the hiring manager showed him a drawer full of applications.

“I says, ‘Well look, I drove down here last night, I got my tools in the truck, I got my clothes, I’m ready to go to work tomorrow morning, this afternoon if you want me to, but I’m not coming back. This is a one-shot deal. If you want me, I’m here right now.”

“I went in Monday and never left,” he said. “I didn’t think that was going to happen.”

That was in 1982. Ronald Reagan was president of the United States. Bill Haggett was president of Bath Iron Works.

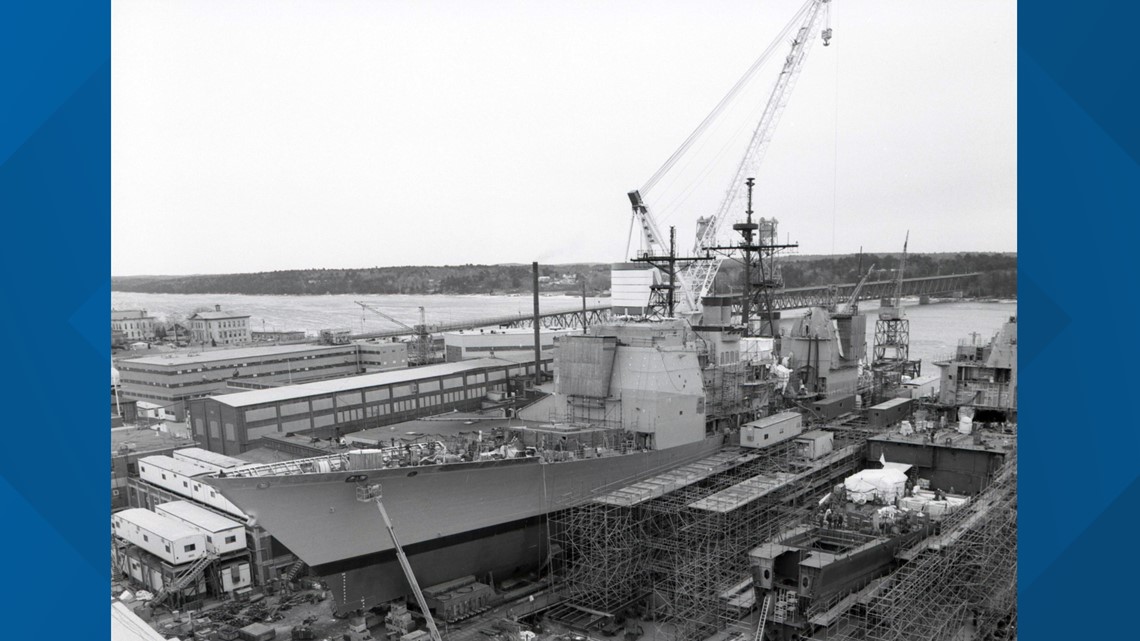

That year, BIW won a contract to build the first of eight Ticonderoga-class cruisers. Three years later, the shipyard won a contract to build the first DDG-51 Arleigh-Burke class destroyer for the U.S. Navy.

Since then, the yard -- one of only two in the world to build the ships for the Navy -- has delivered 37 Arleigh Burkes and three Zumalt-class destroyers, along with Oliver Hazard Perry-class guided missile frigates and Ticondonderoga-class guided missile destroyers.

Back then, Bath launched ships by sliding them off a cradle into the Kennebec River. Today, the ships are built on a cradle set on tracks and moved along a track system into the dry dock and then pulled into the river and sunk so the ship floats free.

Since then, the 138-year-old company has been purchased several times and is now owned by General Dynamics. In 1991, Duane "Buzz" Fitzgerald succeeded Haggett as president of the company. He was followed by Allan Cameron, Dugan Shipway, Jeff Geiger, Fred Harris, Dirk Lesko, and now, Charles "Chuck" Krugh.

Nadeau, who retired this summer after 40 years at BIW, was there for it all.

He and many of the 267 Master Shipbuilders were honored recently at a ceremony at the Bath shipyard.

“This company, it’s not just a job, it’s a career,” Nadeau told NEWS CENTER Maine recently. “The jobs kept coming at me my whole career. Challenges came at me, kept me really interested in the business.”

But during the strike of 1985, Nadeau left the company. Newly married, he and his wife returned to northern Maine.

“I wasn’t coming back,” he said. “I wanted more, wanted my own business."

But he returned to Bath before long, when BIW called to offer him a supervisor’s position.

By 1991, Nadeau worked for the facilities department at the yard. A manager asked him how he’d run things differently.

“I said, ‘Well, I wouldn’t run it like this,’” he said. “I was cocky.”

He told them to study people who run more efficient maintenance operations.

“They said, ‘Well, which shipyard do you want to go to?’ I said, ‘I’m not necessarily thinking shipyard. I think we should try Disneyworld.’ He 'bout fell out of his chair, right? Disneyworld?”

But Nadeau had a plan.

“At the time, that theme park was very successful,” he said. “No one would bring their kids on the rides if they were going to fail, and no one would go twice if they weren’t always up and running. I says, ‘I think they know maintenance pretty well.’”

After arranging a visit through someone at Disney who had served on a Bath-built ship, Nadeau and three other employees spent a week working double-shifts at the Orlando park.

“The place was as large underneath as it was on top,” he said. “Largest dry-cleaning facility in the world, different horticultural facilities, they make their own energy. It’s just phenomenal. They had developed their own software to run their own maintenance.”

Nadeau remembers watching an employee on the teacup ride using a radio to dispatch maintenance workers on the Space Mountain ride.

“Well, we had rotary phones over here,” he said of BIW. “If you gave a guy a job at the beginning of the day, you rarely would see him until the end of the day.”

According to a news report, BIW pared 20 percent off its budget following the trip.

Nadeau later spent 10 years working in environmental health and safety and retired as director of ground assembly.

He credits General Dynamics for the shipyard's longevity.

"They invested several hundred million dollars in this plant, over a period of time," Nadeau said. "Had it not been for them ... we likely would not have a company."

Asked about several strikes by BIW unions during his tenure and negotiations for a new contract set to expire next summer, Nadeau said, "they'll come together as they always have. They'll come together with an agreement, and we'll continue building ships."

"The important thing is that when ship sails down the river on time and the Navy's happy about their product and the sailors who get on that ship are amazed at the product they have to go fight, that's what matters in the end."

Nadeau said BIW employees are rightfully proud of their shipbuilding heritage.

It's all part of BIW's slogan, "Bath built is best built."

"The Roberts was a clear example of that," he said. "The ship was almost split in half, but it floated and saved all the sailors."

In 1988, the Bath-built USS Samuel B Roberts was severely damaged when a mine blew a hole in the port side of the ship. The superstructure didn't sink, though. It was towed to Dubai and ultimately returned to BIW for repairs.

That pride is a crucial part of maintaining a stable workforce. That along with BIW's role as one of two shipyards building DDG 51s will keep BIW building ships well into the future, Nadeau said.

"People have a lot of confidence this shipyard will be here forever, because we're needed in terms of defense," he said.

For years, he said, he reminded his employees of the importance of their work by reminding them of fellow shipyard workers whose own children served on the Navy destroyers built at BIW.

"If you've got children, and they're out there in the Black Sea somewhere or the Pacific, and they get into an attack, you want to make sure when they press that button or move that valve, it’s going to do what it’s supposed to do. It’s going to give all its capability to fight and win.”