NEW GLOUCESTER, Maine — Maine has a well-earned reputation as a craft brewing mecca. For beer and hard cider drinkers, the opportunity to try new flavors and new products seems endless. But for smaller brewers, getting their product to the customer can present challenges. That’s where a company like Iron Heart Canning comes in, bringing the technology and the machinery right to their door.

Noah Fralich is a one-man band when it comes to his business, Norumbega Cidery in New Gloucester. He’s the founder, the owner, the jack of all trades. "To quote King Louis, I am the cidery," he says. He’s been making hard cider for about six years. "Started out real modest, doing all our own pressing, sourcing, bottling in larger format bottles. Bottling by hand definitely is a labor-intensive process and once we signed up with a distributor we really started growing our volume. A couple of years ago we transitioned like everybody else – to cans."

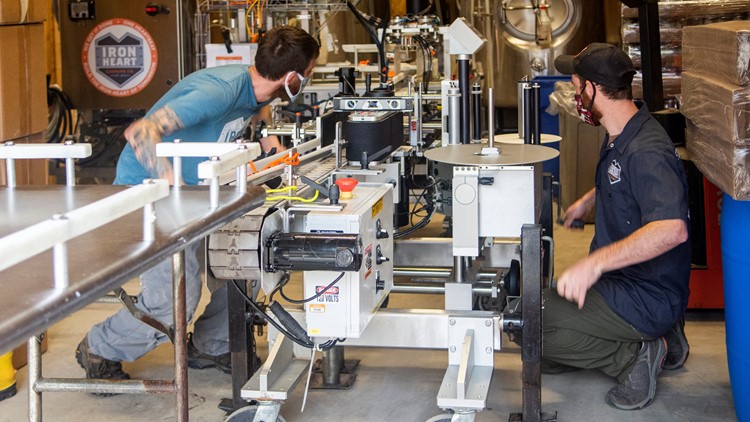

Making the hard cider is one thing – but canning it? That’s something that – at the moment – is way out of his wheelhouse. That’s where Iron Heart Canning comes in. They show up with the technology, machinery, and efficiency of a mobile canning line.

"It really takes a lot of the burden of acquiring expertise and equipment off of me and allows me to focus on what I do and what I started doing which is actually making cider," says Noah. And that’s a pretty big deal for this small operation. Norumbega Cider has been rolling off this assembly line – once a month or so – for the last three years. And it’s meant Noah’s product is now available across most of Maine.

The work begins well before Iron Heart shows up – cans, pack holders, case trays, and lids are all shipped ahead of time to the location. But canning a product – even on a small scale -- requires a lot of equipment. Something most small brewers couldn’t possibly afford – or operate.

Joe Marston is the president of Iron Heart. "There’s a lot of moving parts to make this go well." Moving parts indeed. What rolls out of the back of this truck and seems to magically fit into a small space – looks like something out of a science lab. Each part of the line is rolled into place, secured, and connected. This team is a well-oiled machine. "We have a conveyance system, pulling cans into single file, they go down like a double helix, we call it twist rinse, there is gets sanitized, upside down. It flips back up, and ready for canning on the canning line. We have a CO2 purge that blows out oxygen, and then the filler heads come down and fills the cans up to the level we’ve specified, then it gets lidded, seamed, and then here we have a labeler."

Anthony Caruso joined Iron Heart about five years ago bringing to the job a background in both engineering and brewing. "The best part and the worst part of Iron Heart is going into a small place that they can’t afford a line or they physically can’t fit a line and then watching them grow and being able to afford their own line and expand and then they don’t need us anymore! Making the product as best as we can, trying to package it as best as we can to make it taste good… a month from now… you open it up three months even and it still tastes good - there’s some satisfaction in ‘this was canned properly’ you know."

Iron Heart Canning enables small brewers to reach large markets

Once the process is underway, the team keeps track of the machinery, monitors fill levels, keeps an eye on every part of the process to make sure it is seamless. Once off the line, cans are packed, lidded, and stacked. Today’s work yields 160 cases each of two flavors of Norumbega Cider, ready for distribution.

"Seeing a good day, seeing the look on everybody’s faces, seeing the result. Father-son, husband-wife, family-owned…this is like their life in this facility or whatever the product is that we’re canning. And they want to get it right. We want to get it right for ‘em," reflects Joe Marston.

Noah Fralich is a satisfied customer. "It’s really a whole package that allows you as a small producer to really swing well above your weight and look like you’re a lot bigger than you are."

Iron Heart Canning - which is based in Manchester, New Hampshire - started out with 12 people - now operates mobile canning lines up and down the East Coast and inland as far as Chicago. They will often work with large, well-known brewers as well – perhaps running a small batch of a new product that brewer might want to try out. To learn more, click here.